AQCOLOR is a proprietary technology developed by BenQ to deliver accurate colors on professional monitors. “Colors You Can Trust” is the major benefit that BenQ would like users to experience from products. Reproducing accurate colors is definitely the goal, but how to define "accurate", how to achieve accurate color, and how to prove accurate color has been achieved? These are the questions that we will answer in this article.

AQCOLOR consists of four components, aka the four pillars of AQCOLOR, and each component will be thoroughly discussed in the following paragraphs:

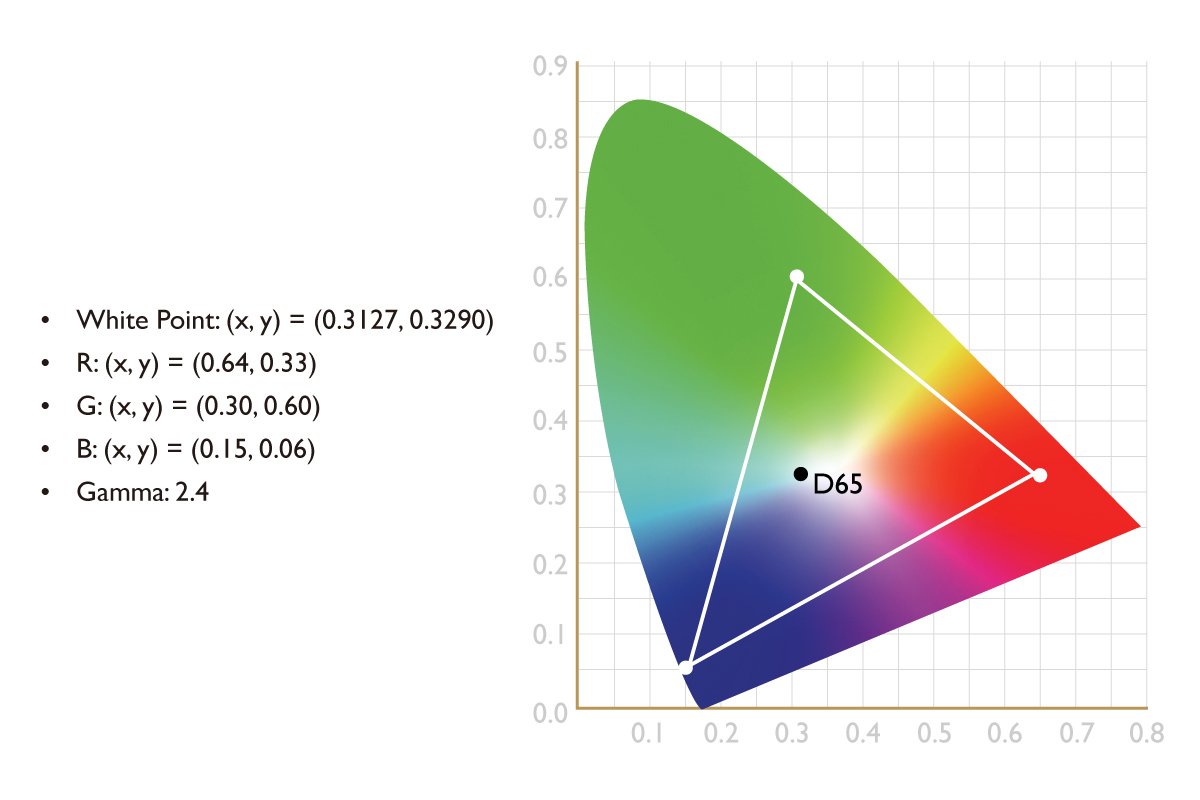

Meeting industry standards is the first step in AQCOLOR technology since this is where all the color requirements and specifications are defined. The industrial standards define the target value which the monitor should be adjusted or calibrated to. For example, ITU-R had approved the Rec. 709 standard in 1990, containing the following color specifications:

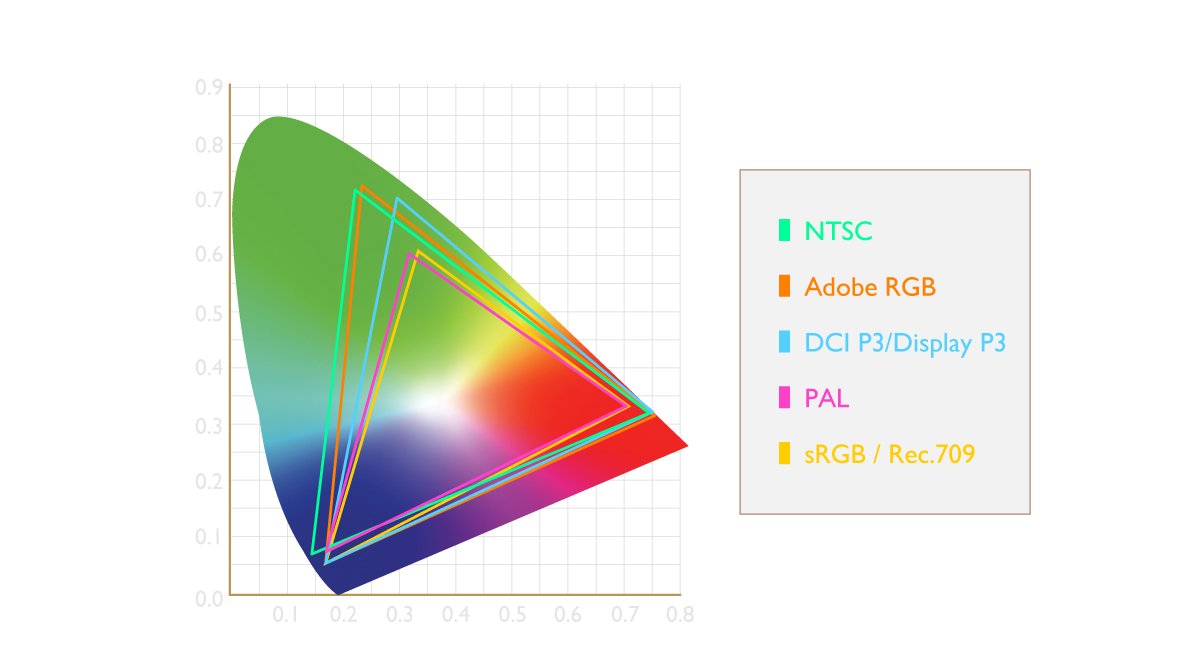

There are many different industrial standards that AQCOLOR follows, and Rec. 709 is only one of them. For the graphical arts industry, both Adobe RGB and sRGB standards are widely used. For the movie industry, the Rec. 709 standard was dominant but with the growth of digital cinema technology, the DCI-P3 standard is now the mainstream of the industry. In broadcasting, NTSC and PAL were both popular earlier, but Rec. 709 has become the majority choice. Among these standards, the largest difference is color gamut, which describes the range of colors a device can reproduce.

Figure 2. Color Gamuts

In order to meet all these industrial standards, BenQ has strived to provide the optimal hardware configuration to build a professional monitor line from the ground up. This includes 10-bit panels with 12/14-bit lookup tables (LUTs) to produce smooth gamma transition and ultra-low delta E to faithfully reproduce standard colors.

Certainly, anyone who cares about colors will calibrate his or her monitor. This also applies to display manufacturers. However, nobody does calibration more seriously than BenQ! Calibration does not only mean the action of placing a measurement device on the panel, but also involves the uniformity of the whole display area, and how to unify the measured results from different measurement devices.

Why is the uniformity of the whole display area important? This is because when we look at the monitor, we are not only looking at one spot but the whole display area. When we place one object in the center of the monitor, we expect the object will look the same at any location of the monitor. However, this is never the case. On a typical monitor, when displaying a full white background, you can definitely see some shades of dark shadows, as shown in Figure 4. This is caused by insufficient diffusion of light from the panel. With BenQ’s unique 1st and 2nd Generation of Uniformity Compensation Technology, this phenomenon can be eliminated. All you can see is a white background without shading or gradations. Hence, now you can be sure any displayed object will appear the same anywhere on the screen.

Figure 4:On the right is the typical monitor, and on the left is the monitor applied with BenQ’s Uniformity Compensation Technology

In a factory setup, there is one measurement device per production line, and there are usually more than one production line. Even though measurement devices are calibrated carefully before each use, there are still discrepancies that may result in divergent visual appearance. As a result, when a user purchases two or more units of the same model, the units may not look alike when they are turned on. With BenQ’s proprietary Color Consistency Technology, measurement devices are aligned and units calibrated look alike. That means users do not need to worry about different monitors not looking consistent. Ultimately, for SW and PV series monitors, we even offer hardware calibration functionality. If at a later stage when factory calibration results start to drift, the hardware calibration function can offer color accuracy which meets industry standards and that can be easily achieved with your calibrator of choice.

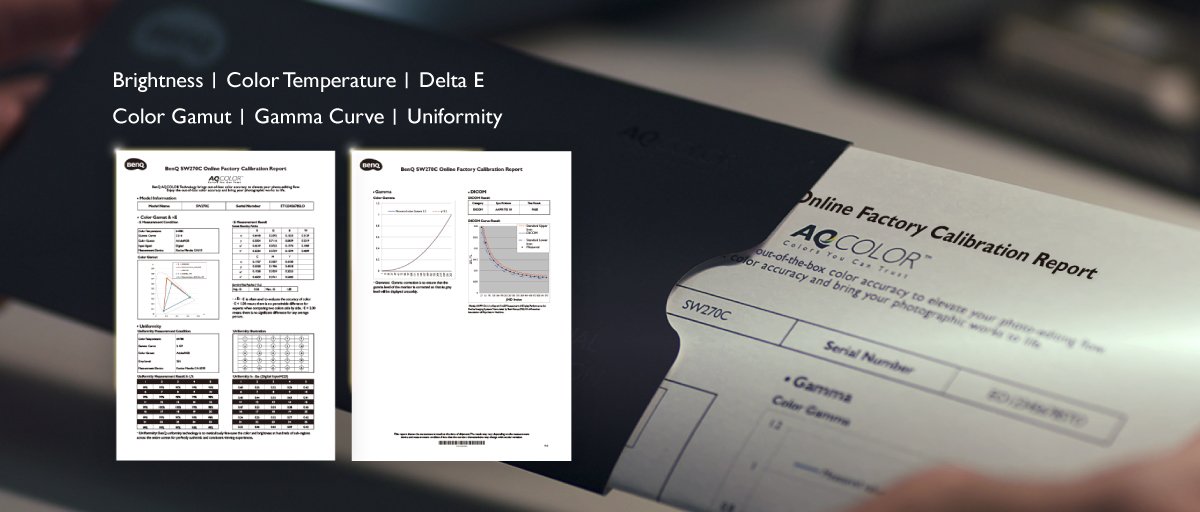

We understand that many users rely on our products for their work. Hence, out-of-the-box performance is of utmost importance to us. This is why we have spent a lot of effort to fine tune our factory preset modes, including Standard, Adobe RGB, sRGB, and DCI-P3 modes. But how do we prove to users that the modes are adjusted to fully meet industry standards? This is where the factory calibration report comes into play. Every unit has its own report bearing its serial number. An example of a factory calibration report is shown in Figure 5. On the report, the following items are clearly indicated to show performance:

Figure 5: BenQ Calibration Report / *Uniformity is available on selected models

With AQCOLOR Technology, BenQ professional monitors have been awarded the Pantone Validated Certificate and Calman Certification. These are third-party color certifications and, in some cases, BenQ is the first to have been awarded. It is not only the products, but AQCOLOR technology that made all these acknowledgments possible.

BenQ has been developing AQCOLOR technology for years, and it is still an evolving process. AQCOLOR technology is built on first meeting industrial standards, then emphasizing display details, followed by an out-of-the-box guarantee. Monitor capabilities are backed by third-party qualifications such as a Pantone Validated Certificate and Calman certification. The goal is to bring out more products that will deliver on the promise “Colors You Can Trust”

Figure 6: BenQ AQCOLOR Technology