How BenQ’s Interactive Displays can minimize the spread of germs in classrooms

- BenQ

- 2020-04-21

New interactive learning techniques are rapidly becoming the norm in the effort to boost student performance. But many of the behaviors that are required for group interactive learning can unknowingly spread dangerous pathogens to other students, their families, and others. This is a relatively new issue in education since the traditional model of using a projector as the primary display limited the physical touching of common objects in the classroom.

In interactive learning environments, students are writing on interactive boards with their fingers, doing group activities together, and maybe solving the same problem side by side on the same display. While these activities help students to learn, they can also be a source to spread pathogens.

Classrooms are only one environment where common items are shared among multiple people. Hospitals are faced with the challenge of delivering quality care using the latest equipment while minimizing the risk of infecting other patients. This has led to the development of medical-grade anti-microbial materials. For example, portable medical isolation care stations are coated with anti-microbial paint to reduce risk to nurses and patients from infection.

Many items found in a surgical theater also have integrated anti-microbial protection such as surgical lighting, touch panels, and other devices that are handled frequently to avoid cross-contamination. In 2018, BenQ was the first company to recognize the opportunity to protect students with the same types of protective coatings that are now common in hospitals.

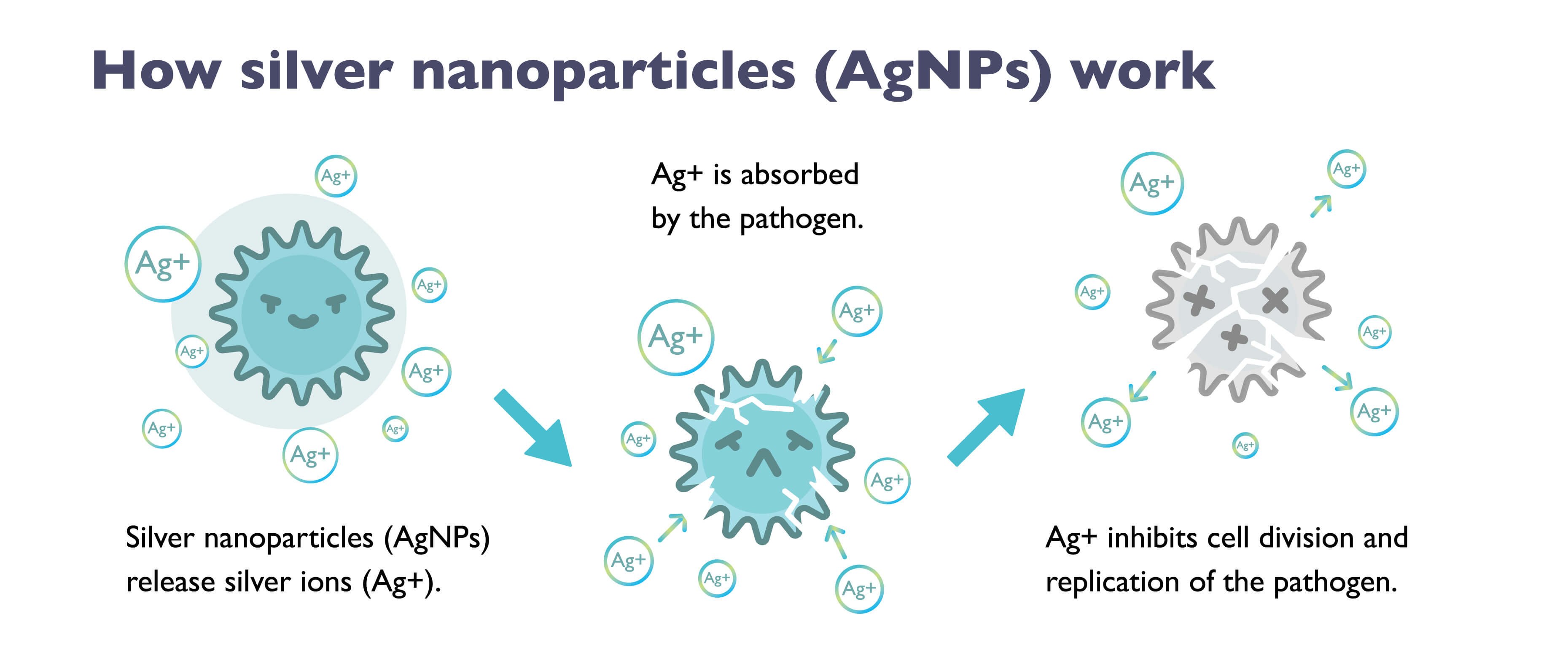

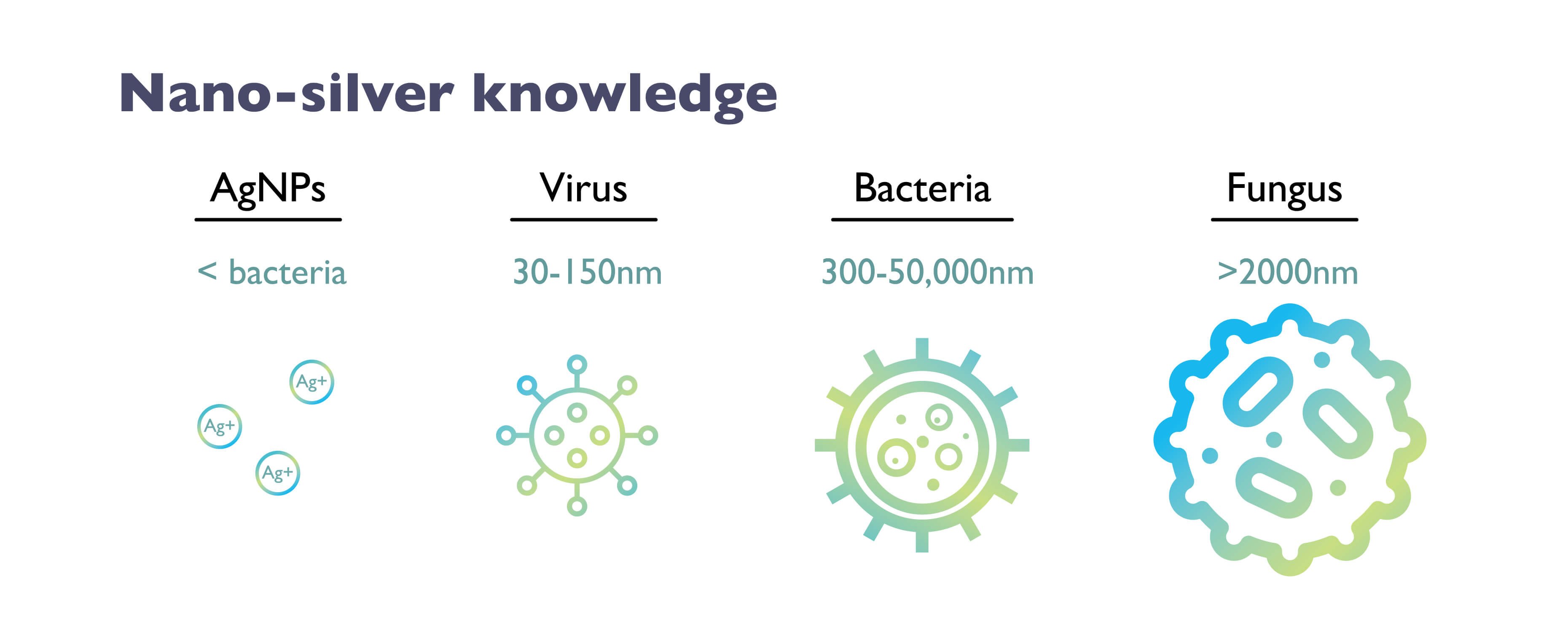

In the days before milk could be pasteurized or refrigerated, people would drop a silver coin into a bottle to preserve it. The development of nanotechnology using silver ion particles was undertaken based on early research from the University of Texas on the effectiveness of reducing bacteria on various surfaces using these different types of metal as active agents, including gold and silver.

In 2011, researchers from the University of Naples published a paper that detailed how silver ion nanotechnology was shown to have positive results in some different virus types This has prompted ongoing research into this technology to improve the efficacy of the technology and broaden the number and types of virus’ that can be controlled. Today there are dozens of scholarly papers from around the world that detail findings on how this technology is used against various types of pathogens.

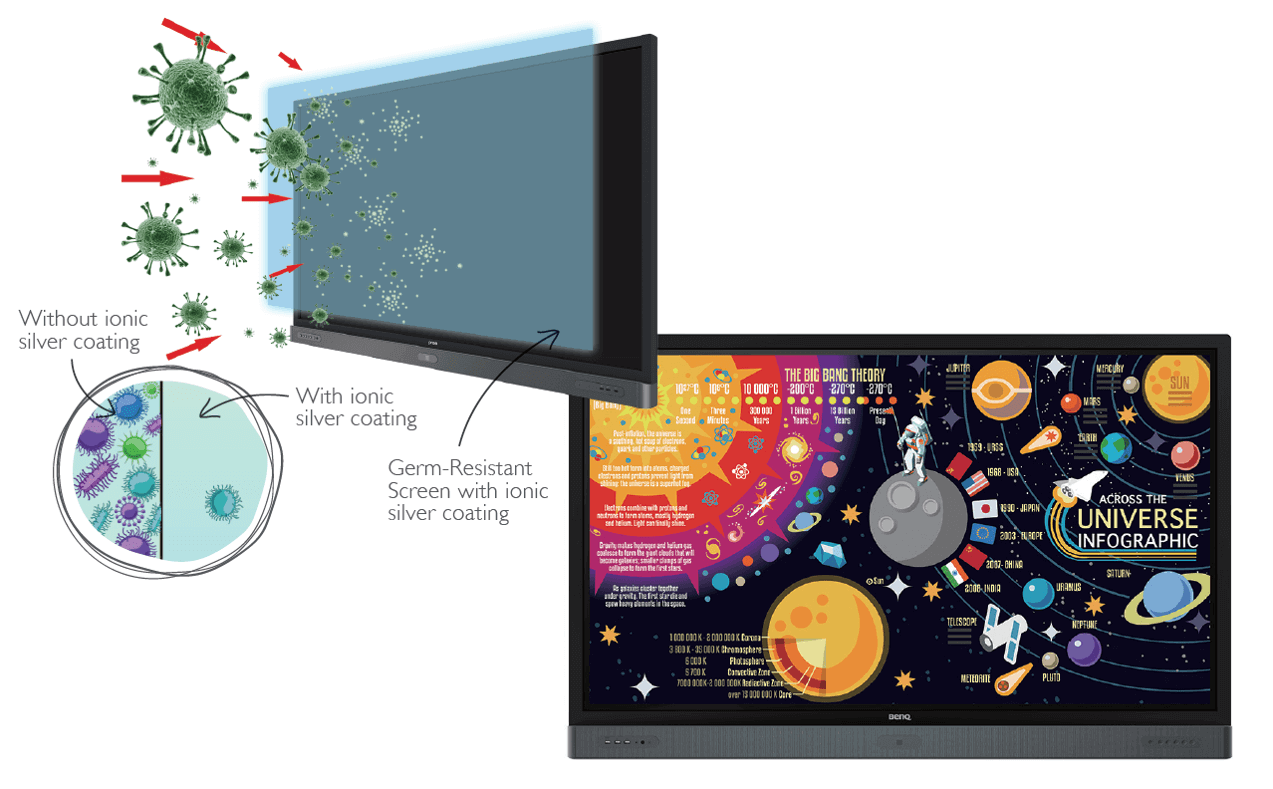

The glass used for interactive displays is quite complex, and coating them with silver ion nanotechnology is a significant engineering challenge, especially given the large size of these displays and the need for other elements such as anti-glare coatings and hardness requirements to keep students from easily breaking the glass.

While the vast majority of interactive displays sold in the US today use standard off-the-shelf glass, the glass used in the BenQ RP series is different. To make the silver-ion coating effective, the glass needs to be coated with the nanoparticles at a special factory, where it is either sandwiched with other coatings (such as anti-glare compounds) or precisely mixed into a proprietary recipe that enables the panel then to be cured. These coatings can be applied to displays as large as 86 inches, but require expensive equipment – and special handling to ensure these large pieces of glass do not crack or break during the process. After the panels are cured, they are sent over to be integrated into the interactive panel frame.

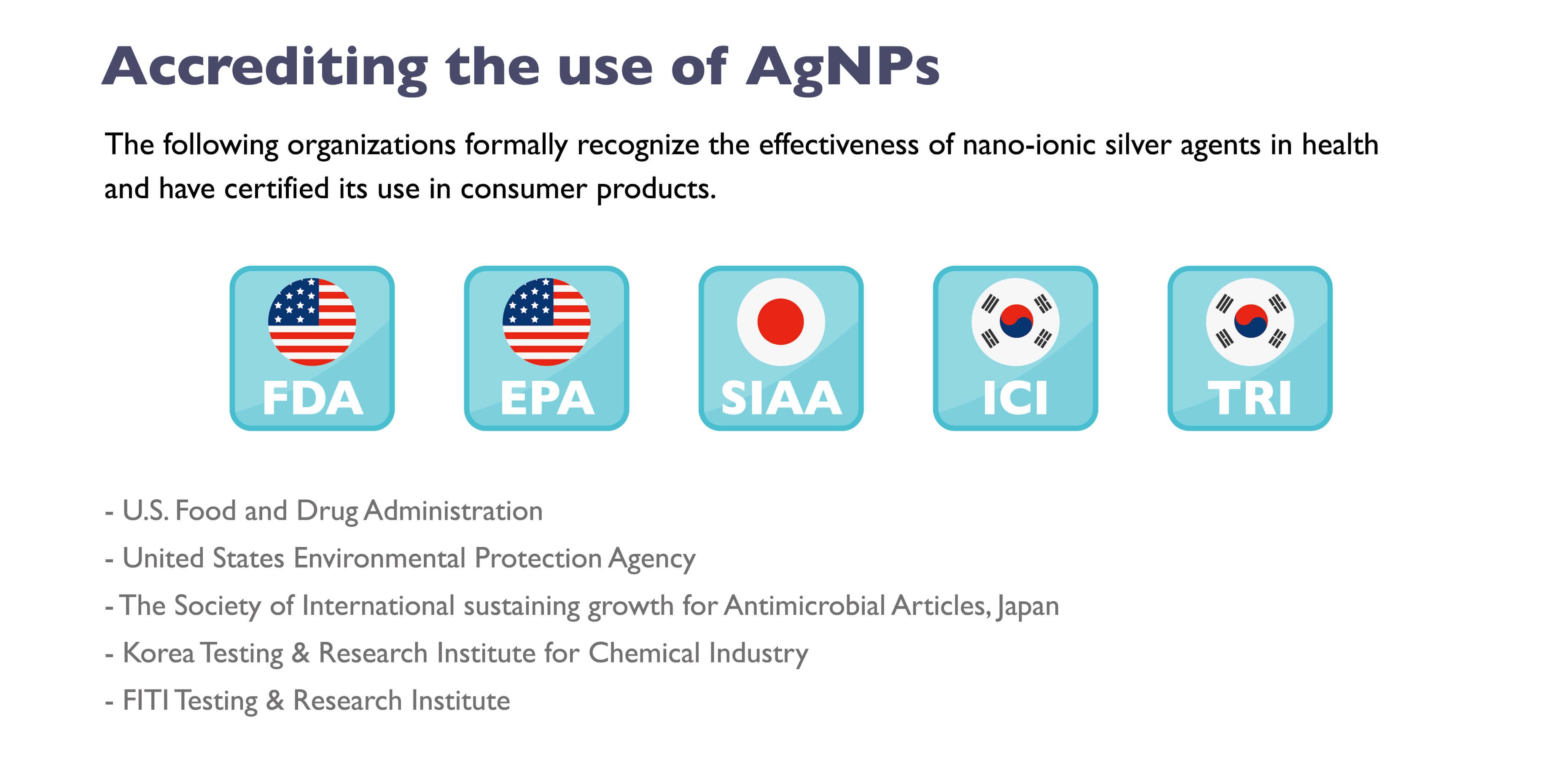

The last part of the process for applying silver ion nanotechnology coating onto interactive flat panels for schools and companies is to validate that it works. History is littered with products that offered health benefits – only to fail when tested by a legitimate third party. To ensure the effectiveness of its silver ion coating, each BenQ model is tested by TÜV.

Headquartered in Munich, Germany TÜV is one of the largest testing and certification labs in the world, with nearly 600,000 issued certificates. For anti-microbial testing, the company has advanced microbiological testing laboratories that validate whether a product provides an effective solution, and certifies it for various types of pathogens.

Each BenQ panel is certified against two major types of bacteria. While the technology may be effective on other types of pathogens, we are the first interactive display with certified results on the two major types of bacteria that represent a significant threat to public health.

E-coli (Escherichia coli)

E-coli is a well-known pathogen and has an exceptionally long life span on surfaces. One study indicates that the bacteria can live 90 days either in the soil or on different types of surfaces. The BenQ interactive panels with silver ion nanotechnology were proven effective at reducing E-coli on the panel.

Staphylococcus

This dangerous bacteria can spread from person to person by direct contact or through contaminated objects, or, less often, by inhalation of infected droplets dispersed by sneezing or coughing. The BenQ coating on its displays was also tested by TÜV and certified to reduce the pathogen on the glass surface.

Using and Maintaining BenQ Interactive Displays

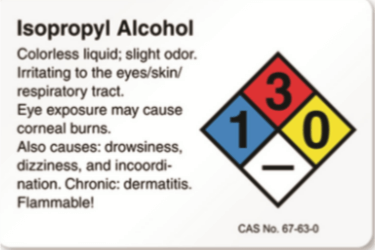

The BenQ panel’s silver ionic coating is fused to the glass, similar to other coatings such as the anti-glare coating. In order to ensure the integrity of both the anti-glare and the anti-microbial coatings, we recommend that the panel be cleaned with a damp cloth (do not spray liquids directly on the screen) using 70% isopropyl alcohol. This formula can also be used to clean the case, tray, and pens that students and teachers will touch.

According to the EPA, this will be effective against both bacteria and virus’ that come into contact with the formula. This has also been tested to ensure the panel coatings are also not compromised. Because the case surrounding the glass has liquid sensitive electronics to track the movement of your pen and fingers, please take care not to expose them to moisture, or use other cleaning products as this may damage the coatings on the screen which could compromise its safety benefits.

All BenQ interactive panels have two additional safety certifications that are important to both education and corporate applications. These functions have also been tested and certified by TÜV for effectiveness.

Low Blue Light

As any professional e-sports gamer or photo editor will confirm, excessive exposure to blue light is something to be avoided. Health researchers at Harvard University have expressed their concern over high levels of blue light, and CNN has reported on studies in Spain that may link excessive exposure to blue light to some types of cancer when exposed to blue light at night. BenQ’s panels all offer a low-blue light mode to reduce your exposure to blue light from the panel.

Flicker-Free LED Backlight

According to research done at the University of Essex in England, certain types of LED light could be responsible for headaches in the right conditions. As one of the largest manufacturers of gaming and engineering monitors in the world, BenQ invented the world’s first flicker-free LED backlight for its displays in 2016. This technology has now been certified by TÜV as eliminating LED flicker, which is especially important when looking at larger sized 75 and 86 inch panels.