Why Glass Lenses are Important for Projectors

- BenQ

- 2019-10-25

Since the invention of glass lenses in the 13th century to help correct nearsightedness, the field of optics with its rigorous demands for quality has helped push the development of the lens manufacturing industry to greater breakthroughs. The timeline of these breakthroughs include Fraunhofer’s research in the 17th century on the refractive effect of glass on sunlight, as well as his work on chromatic dispersion which led to discoveries on how to correct dispersion in telescope lenses. It also includes 1757 when John Dolland used crown and flint glass to produce an achromatic lens. By the 20th century mass production of glass lenses had become common place, with lenses of all types and varieties to suit any need.

Compared to optical glass though, the history behind plastic lenses is much shorter. Just as the First World War had helped push developments in the American optical glass industry, World War II propelled the resin industry in America to discover new materials from which to create lenses.In the following years the demand for plastic lenses blossomed, due in part to stringent shatterproof testing for lenses by the Food and Drug Administration (FDA) of America, as well as trends in fashion such as large-shaped and colored lenses, and as a result the market share for plastic lenses increased.

With the explosion in the use of digital cameras and smartphones in the new millennium and the resulting increase in the use of plastic lenses, the need for more Ultra-precision machining and molding equipments helped trigger advancements in producing more precise plastic lenses. More and more, plastic lenses were able to take on a wider array of shapes and forms, from lenses with non-traditional or aspherical surfaces to extra-large lenses, while at the same time retaining their light-weight nature which made them preferable for use. As a result, projector parts, from lenses to their lighting systems, also increasingly turned to plastics.Despite all this development however, there still remains unavoidable shortcomings when using plastic lenses. These shortcomings include: low transparency for blue light, susceptibility to UV damage, anti-reflective layers that easily detach, low scratch resistance, lack of a high refractive index and low dispersion materials, and weak achromatic capabilities.

Despite all this development however, there still remains unavoidable shortcomings when using plastic lenses. These shortcomings include: low transparency for blue light, susceptibility to UV damage, anti-reflective layers that easily detach, low scratch resistance, lack of a high refractive index and low dispersion materials, and weak achromatic capabilities.

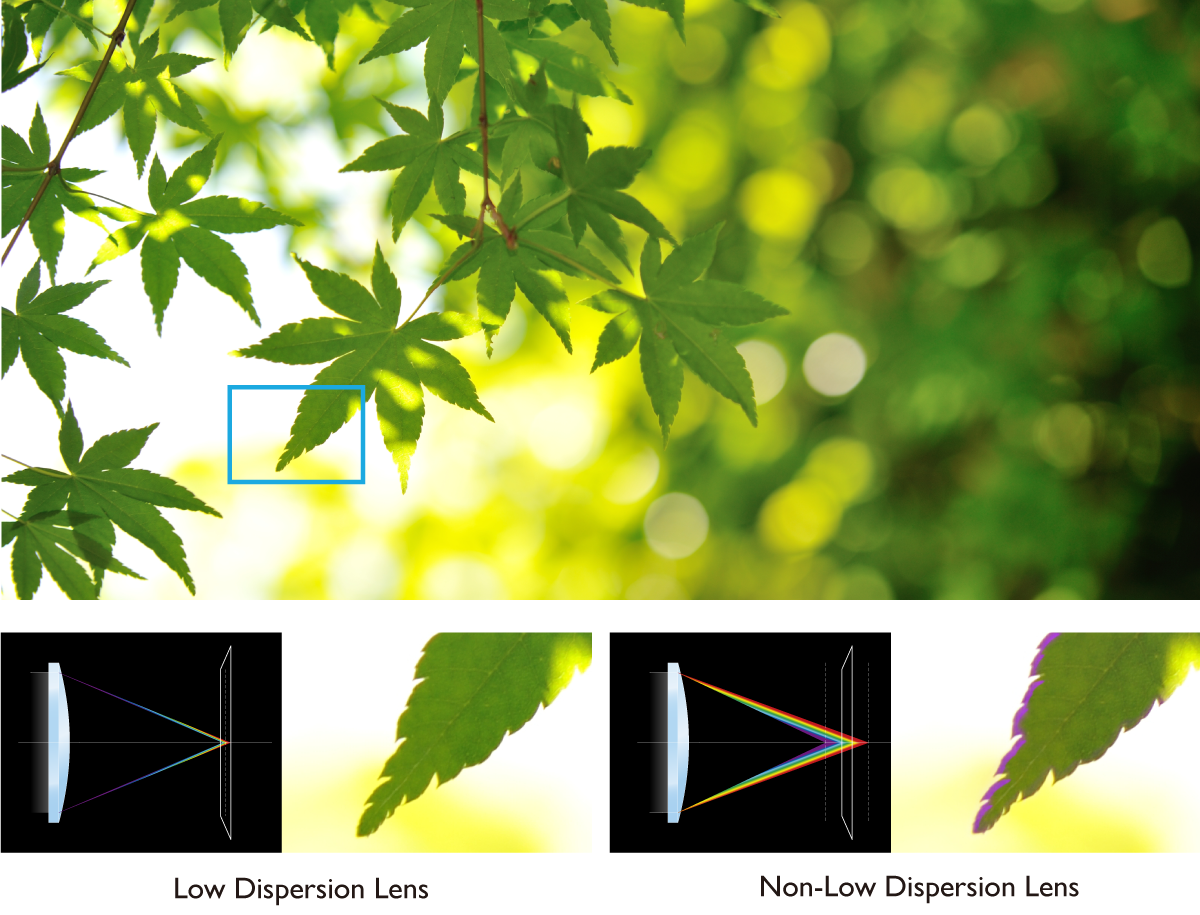

We are in an era where projectors feature brighter and more solid-state light source , which in turn raises the bar for image quality and product life time. In light of this fact BenQ chooses to use full glass lenses in their designs, because when the light is passing through the lenses only the high transparency of precision glass can ensure that the light is presented at its purest without any loss while its high-level of heat-resistance helps preserve image quality and safeguard the image from heat interference. Moreover by the optical design that combine aspherical glass lens and some low-dispersion lenses , BenQ seeks to eliminate image and color defects in order to further refine image quality even in the minutest details.

The use of glass lenses in our projector designs is a choice we make in order to provide the viewer with pristine images that accurately reproduce the details and colors of nature, so that regardless of how much time has passed they can be transported back to the moment when they were first moved by those images.